Process Monitoring

Do manual tests take too much time, delay your response time, impact your product quality and yield and cost your bottom line?

At Thomson Environmental Systems, we have a range of Process Monitoring equipment so we can find the perfect solution for your techincal and site requirements – a solution that will save you time and improve operations.

Process Monitoring

Process Monitoring can be very beneficial in a number of industries. Monitoring of combustion efficiency, Process chemical reactions and for product loose can increase efficiency and product quality and maximise your company profit.

industries include:

- Boilers

- Bio-renewable

- Edible Oils

- Food & Dairy

- Alumina Refining

- Cement Plants

- Pulp & Paper

- Power Generation

- Pharmaceuticals

- Landfill and biogas

- Bulk and specialty gases & system

- Air separation and nitrogen plants

- Hydrogen production & quality control

Research

Featured Equipment

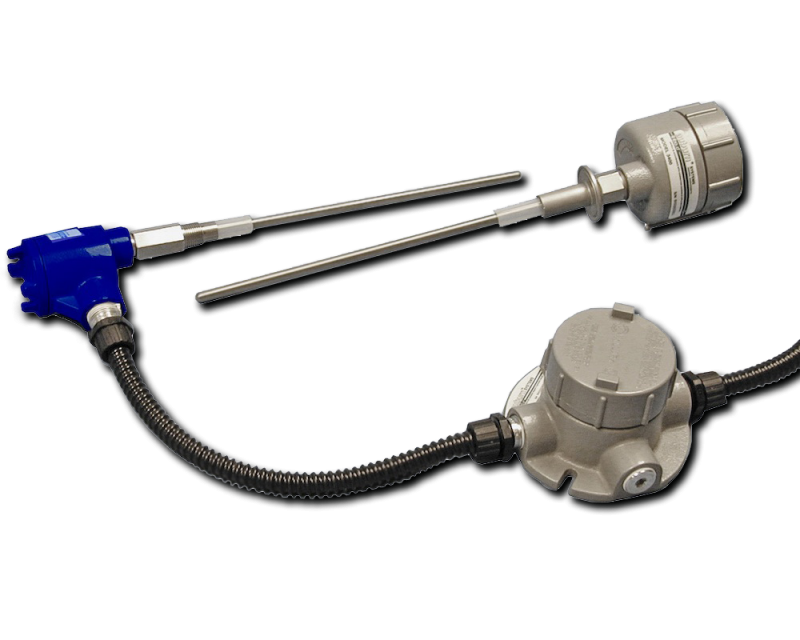

Auburn Filter Sense PM 1 Pro

DynaCharge – As particles flow by a sensor, charge is induced into the sensor creating small currents in the picoamp (pA) range. The signal is processed into an output proportional to mass.

Features:

- Fully insulated probes prevent false readings from moisture, corrosives, and most conductive particles – without air purge = Prevents False Alarms.

- Low cost, reliable sensors = allows client to maximise baghouse filter life, reduce product lost and minimise environmental impact.

- Remote or integrated electronics – pick system to suit your installation requirements.

Self-test circuits (zero, upscale/span, linearity and sensor condition), and high precision options enable meeting EPA quality assurance, and relative mass accuracy specifications in standards such as, but not limited to, ASTM D7392 and EN 15859.

Single sided, various connectors available including flange and quick clamp

Auburn Filtersense

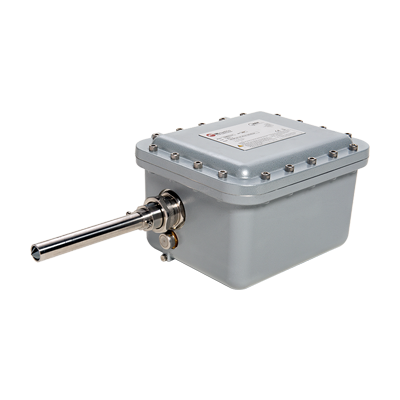

Keit IRmadillo with integrated controller

The IRmadillo is a vibration-tolerant, mid-infrared process spectrometer designed to enable monitoring of either batch or continuous processes of liquids in a range of industries.

Unlike conventional FTIR spectrometers, the IRmadillo has no moving parts making it extremely resistant to vibration and therefore able to be used directly in the manufacturing environment. It can be fixed directly onto the side of a reaction vessel or pipe at the point of production rather than remotely located. This enables manufacturers to continuously monitor their chemical reactions in real time with an in-line analytical instrument. The IRmadillo is an innovation in process analytical technology that changes how manufacturers can monitor and control their processes.

Features:

- Process optimisation requires online measurement of key properties – payback in energy, yield and quality

- Real-time information contextualised with sensor, process and equipment data for agile manufacturing

- Patented design with no moving parts – once aligned, it stays aligned which means low running costs (minimal maintenance)

ATSM 2101 and EN 14683 |

Oil & Gas, Petrochemical, Bio-renewables, Pharmaceuticals, Edible Oils, Alumina Refining, Pulp & Paper

The IRmadillo has no moving parts and a rigid probe which is inserted directly into the reaction vessel or process pipeline for continuous real-time analysis

Keit Industrial Analytics

Process Equipment

Frequently Asked Questions

Yes, Auburn Filtersense offer reliable, accurate Dynacharge technology that allow you to trend and pre-empt a bag l break. Check out PM 1 Pro

Absolutely, Measuring chemical reactions in manufacturing environments can be difficult and costly. With the IRmadillo, a compact and tough in-line FTIR spectrometer from Keit Industrial Analytics, you can get powerful real-time analysis right at the point of production – saving you time and money.

All Equipment supplied by TES in Australia and New Zealand is supported by TES. We have factory trained technicians located strategically around the region and stocked spare parts. TES can assist with client Design, supply, installation, commissioning and on going maintenance if required.

Yes TES offer a range of Dust and Gas monitoring with IEC Ex ratings.

let's find your

Process monitoring solution

If your equipment doesn’t do its job properly, you can’t do yours. Let’s find you a reliable, high quality solution to meet your requirements and make your life easier.

- BROWSE OUR PRODUCTS

View our product portfolio online. Use our advanced search to filter by industry, application, parameter or brand.

- CONTACT YOUR LOCAL REP

With offices across Australia in NSW, QLD, ACT, VIC and WA we have a local office nearby waiting to help. For our customers in Africa we have an office in Ghana. If you’re in New Zealand or elsewhere overseas, we have dedicated team member ready to help with whatever you need.

- FIND YOUR SOLUTION

Whether you have a license requirement, specification needs or external considerations, our team of experts can guide you to the right solution.