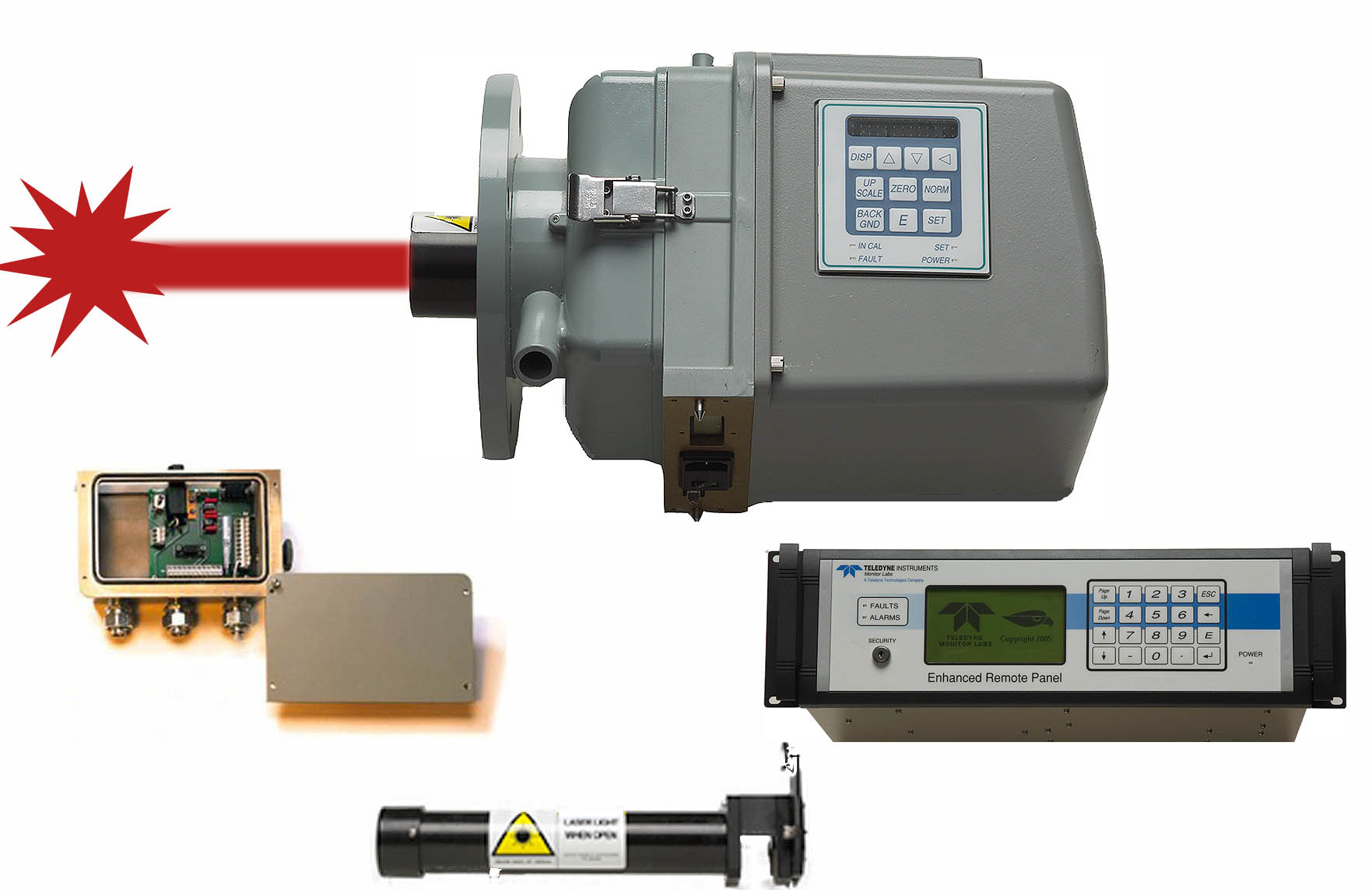

The heart of the Laserhawk® Dust Monitor is an electronically modulated (2400Hz), intensity controlled solid-state red laser located in the Optical Head assembly. A beam from the laser is projected from the Optical Head into the stack and along a path through the effluent. The laser beam is reflected, refracted, absorbed and scattered in all directions by the particulate matter including in the backwards direction. The scattered light re-enters the Optical Head, where it is evaluated by a signal detector. The measured signal is correlated to dust concentration using either a linear, exponential or polynomial correlation curve. The dust concentration is provided in units of mg/m3 (or grains/dscf). Zero and upscale calibration drift tests are conducted utilizing a superior anti-vibration calibration mechanism design. The unit is displays extremely low drift and is sure to operate in the widest variety of applications.

LaserHawk Model 360 Brochure

LaserHawk Optical Head

The Optical Head is housed in rugged NEMA 4 aluminum castings. The Optical Head contains the active electronics necessary to project a laser beam across the stack/duct to the Retroreflector assembly and to detect reflected light. The sealed Optical Head subassembly is designed for simple cover removal, allowing complete access to the electronics.

Purge System

A purge air system is furnished with each LaserHawk®. The system supplies purge air to the Optical Head, protecting the instruments from stack gases and significantly reducing maintenance intervals. A Purge Air sensing switch is provided in case of power loss or interruption. Purge fail/power fail alarms are standard.

Optical Head Keyboard/Display

Uses a 10 button keypad & 6 digit readout to display and/or enter:

- Instantaneous Particulate Concentration (mg/m3 or gr/ft3)

- Average Particulate Concentration

- Upscale Calibration

- Zero Calibration

- Dust Compensation

- Status Codes

- Diagnostic Data about the Analog Signals Inside the Optical Head (no need to open the Optical Head)

- Particulate Concentration Curves

- Optical Gains

- Alarm Settings.

With optional Six Point I/O board, LaserHawk® meets all PS-11 requirements without a Remote Display Panel.

Enhanced Remote Panel

Uses a large, back-lit, LCD graphics display with English-language, menu driven screens, providing ready access to all information needed for full use of the system. In addition, the user can graph up to the most recent 100 values of a selected parameter, such as:

- Instantaneous dust concentration, average dust concentration

- Calibration Values (Zero, Upscale, or Dust Compensation)

The keypad, a rugged 20-button ensemble inlaid under a tough, hard coated, scratch and chemical-resistant Lexan coating, can be used to:

- Display Dust Concentration in mg/m3 or gr/ft3 basis

- Identify the Cause of an Alarm or Malfunction

- Configure the Relay Outputs

- Configure the Analog Outputs

- Edit Parameters such as Voltages, Currents, and Gains

- Set Alarm Values for Dust Concentration, Zero Cal and Upscale Cal

- Load Correlation Curves for Particulate Concentration.

Calibration Kit

The calibration kit, standard with the LaserHawk®, is used as an additional check of the unit’s proper operation and calibration. The calibration fixture attaches to the front face of the optical head and has been preset to return the same amount of light as the retroreflector when the stack or duct is clear.

Ethernet Interface

The LaserHawk® Enhanced Remote Panel now features 10/100 Based Ethernet interface as standard equipment. This capability provides a multilevel password protected interface to TCP/IP networks such as LAN’s or the Internet. Client side user interface access is via standard web browsers. Simultaneous Modbus TCP access to instrument parameters and emission data is also supported.

Features

Meets EPA Performance Specification-11

The Laserhawk® was designed to Comply with the performance specification for continuous particulate monitors. A complete system includes an optical head, purge system, enhanced remote panel operate fulfilling all QA/QC requirements.

Rugged construction holds up under toughest conditions

The Optical Head is built of heavy gauge aluminum parts and finished with acid-resistant enamel paint. All exposed hardware is stainless steel. The rugged design and extremely low heat generation allows operation over a wide range of ambient temperatures. It is built to withstand the typical hostile environment associated with outdoor industrial applications, including substantial shock and vibration.

Labor saving on-stack controls

All of the hardware and software needed for the system setup, control and maintenance are packaged within a single optical housing. Via a membrane-sealed keypad and digital display, the user can perform clear-stack zeroing, span/zero setup, reset window dirt calculation following maintenance, input dust load correlation data, and access the full set of diagnostic parameters.

Ideal for OEM Applications

The LaserHawk® is easy to calibrate but for ideal accuracy should be calibrated on-site using Method 5 or 17 isokinetic testing by a third party. Once the linear, exponential or polynomial correlation curve is input via the keypads on either the Optical Head or Enhanced Remote Panel, the cal kit can be used to set up zero, low, medium and high energy levels in the appropriate scale. User friendly menus on the keypads enable adjustment of gains and currents to ensure proper operation of the monitor. No potentiometer adjustments or resistor changes are required. Instantaneous or average dust concentration can be transmitted directly to a DAS or if the optional Six Point I/O module is used via optically isolated analog signals, network or serial communication.

Advanced optical design for consistent operation

Some scattering monitors don’t operate well in heat, high noon conditions or when stack or duct walls shift slightly due to temperature, wind, etc. Not the LaserHawk®. Its electronically modulated intensity-controlled solid state laser beam ensures unusually stable operation, without interference from sunlight, room lights, or back wall scattered energy. The monochromatic, coherent red laser beam has no alignment issues since the beam shines directly into the stack requiring no reflector assembly.

Flexible trouble-free operation

The Optical Head and Enhanced Remote Panel of the LaserHawk® are interconnected via a LonWorks protocol, using transformer isolated data lines which nearly eliminate the potential effects of electro-static discharge. This approach provides great flexibility in choices of options and interconnects topology. One twisted pair is required for each system interconnection. The Optical Head and Remote Panel provide all parameters needed for maintenance and diagnostics. It is easily configured to any plant Digital Control System, Data Acquisition System, or control system.

Commonality of Parts

TML has paralleled the design of the Laserhawk® off of its Model 560 Lighthawk® Compliance Opacity monitor and the Ultraflow-150 Ultrasonic Flow Monitor. All utilize the same Enhanced Remote Panel; communication protocols, and mounting hardware. This saves the customer valuable inventory dollars and permits the use of spares on a variety of equipment.

Optional equipment

Optional equipment with the LaserHawk® includes; optional flange nozzle materials, high-temperature hardware, adapter flanges, and separate packaging of the I/O Module. Consult factory for application criteria and options for wet stacks or small diameter stacks.