Protect your process with the HALO QRP

Modern semiconductor deposition processes — from low-temperature epitaxy to ALD and MOCVD — operate routinely at chamber pressures far below atmosphere and approach the single-digit torr range. At the same time, process temperatures are continuously decreasing. Under these conditions, residual moisture in the chamber poses a significant threat to process quality and production yields.

Tiger Optics’ new HALO QRP is optimised to operate under these low-pressure conditions and deliver exact and reliable real-time measurement to verify moisture residue in, for example, the load lock, transfer and process chambers before H2O contaminants compromise the subsequent process step. Based on Tiger Optics’ proven Continuous-Wave Cavity Ring-Down Spectroscopy (CW-CRDS) technology, the HALO QRP sets new standards in ease-of-use and measurement precision for this application, and operates at chamber pressures as low as 1 Torr.

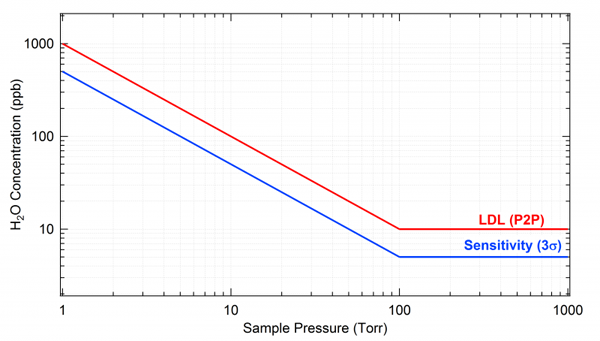

Designed for trace level moisture analysis in low pressure (<50 Torr) applications, the HALO QRP offers:

- Moisture detection at partial pressure of 1 µTorr and below

- Absolute accuracy and excellent precision

- Wide dynamic range—over four orders of magnitude

- Low cost of ownership and operational simplicity

- Clean technology—no external calibration gases required

- Compact analyzer footprint, also available as OEM module for equipment/system integration.

Detection Limit and Sensitivity in Concentration Units (ppb)

Applications

- Gas Quality Control

- UHP Ammonia & High-Brightness LEDs

- Research & Development

- Semiconductor Process Tools.