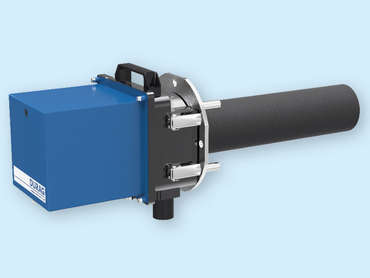

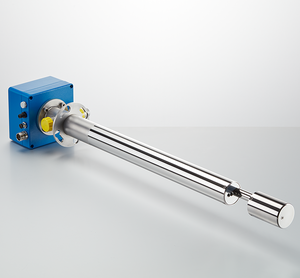

The DURAG D-R 320 is a scattered light dust monitor that detects the lowest to medium dust concentrations in dry flue and process gas.

The D-R 320 is based on the back-scattered light principle – the light of a red laser diode illuminates the dust particles in the measuring volume of the flue gas duct. The light scattered backward by these particles is detected and evaluated.

A unique feature of the D-R 320 is the automatic background light compensation with means of a patented optical system with dual detector. This allows for an easy and quick installation without any adjustment. A light trap is not required.

Key Benefits

- single sided installation on a standard flange

- easy startup without adjustment

- automatic background light compensation without light trap

- automatic zero and reference point check

- automatic contamination control and correction

- integrated purge air regulation and purge air control

- minimum maintenance

- EN 15267 certified

- digital interface according to VDI 4201-3

Applications

Continuous emission monitoring, e.g:

- on incineration plants generally

- on plants according to IED 2010/75/EU

- on waste, hazardous waste and sewage sludge incineration plants

- on cement manufacturing plants

- on power plants with gas, oil, coal or co-firing

- on plants for the incineration of biomass

Monitoring of:

- ventilation units

- filter units